Industry

4.0

Industry 4.0 in OTS Group

We are industry 4.0 in all product design and manufacturing processes.

The interconnection is complete in our facilities and production processes.

A new reality: Industry 4.0, holistic process and lean manufacturing

The new methodologies allow us to deal with this current reality using the greatest possible guarantees.

- Industry 4.0:

We are industry 4.0 in all product design and manufacturing processes. The interconnection is complete in our facilities and production processes. - Holistic process

Our process allows us to have full control of each of the projects that OTS Group takes on. Through our know how, fantastic results can be achieved. - Lean manufacturing

We apply the LEAN methodology, analysing and creating improvements in our processes. We actively collaborate with all departments of the organisation, seeking improvement throughout all production and administrative processes.

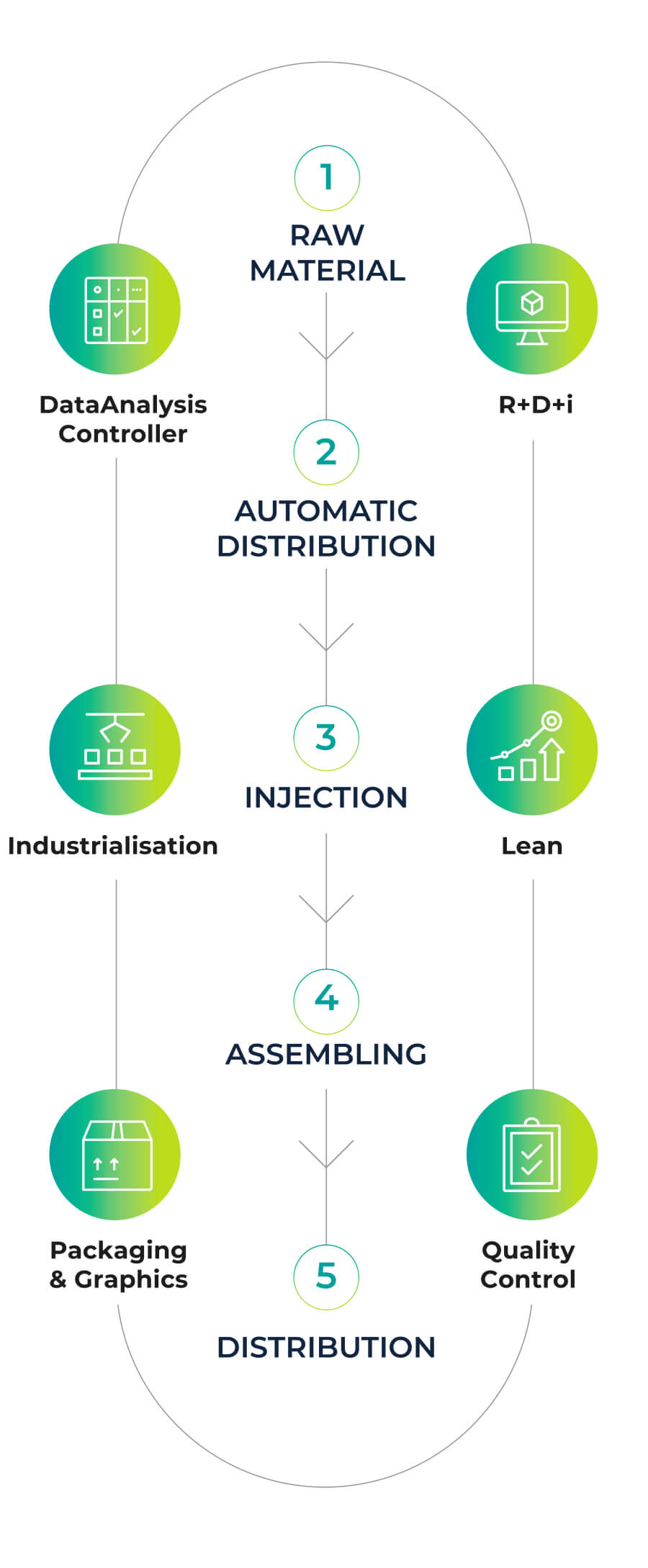

Our production process

We work with a management model that applies the lean manufacturing methodology to control the entire industrial process in our own production plant, from engineering and design to the manufacturing chain, adapting our know-how to the needs of each project.

OTS in figures

At OTS Group, our commitment to quality and innovation is complete and for this reason we have cutting-edge resources that allow us to offer the best results

7.500 m²

of facilities

Robots

20 robotic machines

Comprehensive service

with 3 autonomous business units

0 waste

thanks to the collaborative robots

Production on demand

20 Engel injection machines between 50 - 1,500 T

Industry 4.0

Koch Technik

Automated raw material intrologistics

Injection

technologies

- Conventional injection

- Overmoulding

- Gas-assisted injection

- In-mould decoration

Production

technologies

- Post-injection processes

- Machining of thermoplastic

- Ultrasonic welding

- Assembly lines

- Construction and maintenance of moulds

Technologies

for decoration

- Hot stamping printing

- Pad printing

- Tracing

- Vinyl

- Painting

- Chrome

Our value proposal

Customisation

Customised design

Multiple finishes and textures

Limitless creativity

Innovation

Research labs

Technical materials

Research / innovation at the service of the client

Comprehensive project management

Project planning

Registration and risk management

Process optimisation

Turnkey service

Technical engineering device

From concept to engineering

Viability and product design

Process engineering

Customer service methodology

Materials

Use of Koch-Technik system, an automatic feed system for raw materials.

Comprehensive control of temperature, humidity and cleanliness of pipes to achieve optimal injection conditions.

Processes

Automation of production, assembly, palletising and packaging systems.

OTS Group puts all its strength, machinery and expertise at the service of its clients. That is why it is undoubtedly your best solution.

Would you like to get in touch with OTS Group?